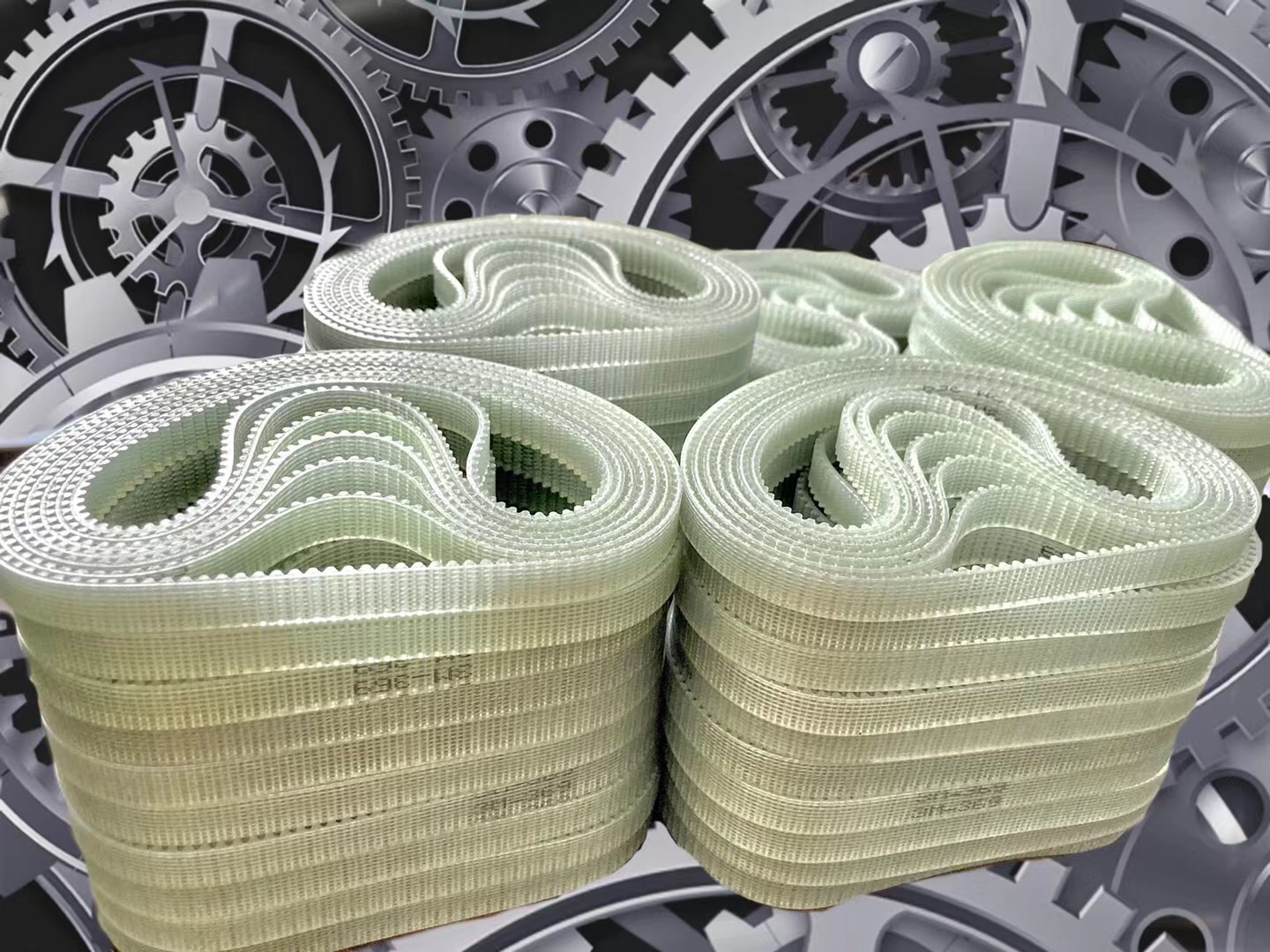

In the world of power transmission, timing belts are a critical component for ensuring synchronized movement between mechanical elements. While rubber timing belts are widely used, polyurethane (PU) timing belts offer significant advantages in specific environments and use cases.

So when should you consider polyurethane belts over traditional rubber ones?

Polyurethane belts are exceptionally resistant to wear, abrasion, and tearing. In systems with frequent start-stop cycles, high-speed operation, or constant friction, PU belts last longer and maintain performance.

Best for: Packaging machines, textile equipment, friction-heavy conveyors.

PU belts withstand oils, greases, and many chemicals much better than rubber. Rubber belts tend to swell, crack, or degrade when exposed to chemicals, reducing their service life.

Best for: Food processing lines, pharmaceutical packaging, chemical handling systems.

Polyurethane performs well in a broader temperature range than rubber — often from -30°C to +80°C (or more with special formulations). Rubber can harden in cold or soften in heat.

Best for: Cold storage conveyors, outdoor automation, heated enclosures.

PU timing belts are manufactured with high dimensional accuracy and can be reinforced with steel or Kevlar cords. This minimizes stretch and improves positioning accuracy.

Best for: CNC machines, robots, 3D printers, servo-driven systems.

Polyurethane belts are clean, non-toxic, and easy to sanitize. Rubber belts may generate dust and are harder to keep hygienic.

Best for: Medical devices, food automation, cleanroom conveyors.

PU belts can be produced as open-ended, welded loops, or custom profiles with cleats, backings, or coatings. This is ideal for specialized conveyors or synchronizing multiple axes.

Best for: Custom automation, vertical conveyors, synchronized transport.

While rubber timing belts remain a practical choice for many standard applications, polyurethane timing belts deliver better performance in:

Choose polyurethane when you need reliability, accuracy, and durability — even in the toughest conditions.

Need help selecting the right PU belt for your system? Contact us for expert advice or request a quote.

Contact: Jiver

Phone: 13586029060

Email: sales@industrial-belt.com

Shangye Haiyou Town Sanmen Zhejiang China 317100